Connects: Frying Pan Road (CR 104)

![]()

![]()

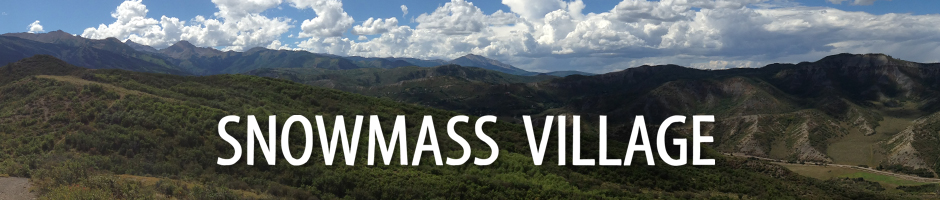

The Thomasville Lime Kilns along Frying Pan Road

Thomasville, CO – Lime Kilns

The Thomasville Lime Kilns were built in 1888 and are some of the largest in existence. This is a site near Reudi Reservoir in Thomasville, CO.

These lime kilns were built in 1888 and are some of the largest lime kilns in existence today. The kilns were built to convert limestone (Calcium Carbonate) to quick lime (Calcium Oxide) under very high temperatures by a process known as calcination.

Lime burning has been taking place for centuries with the earliest records dating back to 2450 BC. Making lime during the late 1880s was a time consuming, dangerous and labor intensive process. Limestone rock was quarried and transported to the kiln; wood and/or charcoal was needed to fire the kiln and transportation for the final product needed to be nearby. Danger lay in all parts of the work, which was most dramatically demonstrated by the explosion of the northern most kiln sometime in the 1920s, killing one worker.

The limestone used in these kilns was quarried from the hillside above and from another site across the river. The limestone was then loaded into the cylindrical center of the kiln from the top. A very hot fire was built at the bottom of the cylindrical chamber to cook the limestone at over 900°C (1642°F). This fire was tended through the large arched opening in the front and from smaller openings on the side of the kiln. It took several days to complete the chemical reaction.

The quick lime created by these kilns was used primary in the manufacturing of portland cement and for neutralizing acetic soils, locally. Lime was also used regionally as a flux in smelting iron and lead, and in the purification of sugar beet juice.

Four kilns originally existed on this site and at the height of operations, in 1905, a Colorado Midland freight train left Thomasville loaded with 153 cars of quick lime and 12 cars of limestone.

The construction of the Colorado Midland Railroad made the production of lime at this site possible. As a result, this and other small industries along the line supported the growth of small camps into more substantial communities up and down the Valley.

The railroad tracks were removed in 1921, leaving the grade for the current road. The kilns were shut down in 1908 but were re-opened periodically thereafter until 1938.

The kilns were abandoned in 1938, and by 2001, in danger of collapse, they were listed on Colorado’s Most Endangered Places list. In 2006, Pitkin County completed a stabilization project, made possible by a grant form the Colorado Department of Transportation (CDOT).

Special Thanks to: Pitkin County Board of County Commissioners, Colorado Department of Transportation, JVA Project Architect and Engineer, The Opal Group – Contractor, Preservation Technology Inc. – Masonry Subcontractor, Colorado Preservation Inc, Colorado Office of Historic Preservation and Archeology, Basalt Fire Department, Upper Fryingpan Valley Caucus, the Roger’s Family, and Henry and Marilyn Lee, for use of the images.”

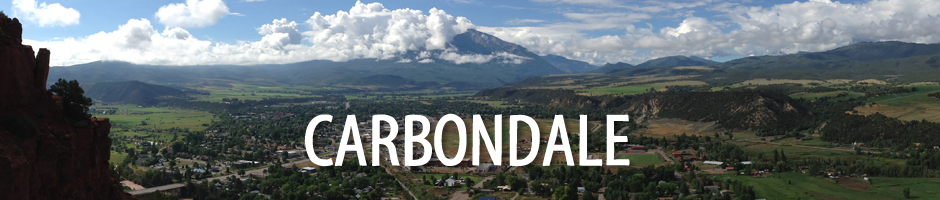

This area of Pitkin County was settled in the 1880s. The numerous settlements along the upper Frying Pan Valley area grew up around the route of the Colorado Midland Railroad. until 1885 the valleys of the Roaring Fork drainage were accessible only by foot, horse, and mule and the mineral wealth could not be fully realized until more efficient modes of transportation could be established. In the early 1880s, two railroads were in competition to reach the valley floor first and establish themselves to claim their share of the wealth. The Denver & Rio Grande Railroad, a narrow gauge railway, chose to extend its route from Leadville, through Glenwood Canyon alongside the Colorado River to Glenwood Springs. The Colorado Midland chose to extend its standard gauge line from Leadville by way of a tunnel through the Continental Divide connecting Leadville and the head of the Frying Pan Valley, then proceeding down to the Roaring Fork Valley Floor. The Denver & Rio Grande arrived in Aspen in October of 1887, ahead of Colorado Midland by only a few months.

The completed Colorado Midland Railroad was the only standard gauge route in the Colorado high country and traveled along the alignment of this road between Leadville and Basalt. The total length of the rail line was 261 miles. Depending in the era in which you traveled, it featured up to 18 tunnels of various lengths. The longest was almost 2 miles long while others were very short. The Hagerman Tunnel, which crossed under the Continental Divide, is 2,200 feel long and sits at over 11,000 feet above sea level. The construction of the route was an engineering marvel. The tunnels, bridges and the railroad bed were constructed by hundreds of men using dynamite, picks and shovels, summer and winter. Mules and wagons are the only form of transportation. Camps were established to support the workers and these camps quickly grew into established communities that lived on beyond the railroad construction.

These communities included Ruedi, which was located where the reservoir now sits, Meredith, Norrie, Sellar, and Nast, among some others. These communities had their own identities and niches, and thrived because of the Colorado Midland Railroad.

This sites was originally known as Calcium, named for the lime processing industry that was centered here once the railroad was established. The Lime Kilns, located across the road, are the last remnants of that industry. The Calcium community eventually became part of Thomasville, which still exists today.

The Railroad ran until 1921 and supported the business of numerous communities along the route. It also made the Frying Pan Valley popular for sightseers. Even when it was first being settled, tourists would ride the train up from Leadville to pick wildflowers.

Special Thanks to: Pitkin County Board of County Commissioners, Colorado Department of Transportation, JVA Project Architect and Engineer, The Opal Group – Contractor, Preservation Technology Inc. – Masonry Subcontractor, Colorado Preservation Inc, Colorado Office of Historic Preservation and Archeology, Basalt Fire Department, Upper Fryingpan Valley Caucus, the Roger’s Family, and Henry and Marilyn Lee, for use of the images.”